FLEX JOINT HOOK & RECEIVER

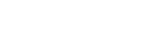

The flex joint hook and receiver is another Reinke engineering innovation. The hook and receiver is a pipe joint that allows our irrigation systems to traverse difficult terrain with minimal impact on water flow.

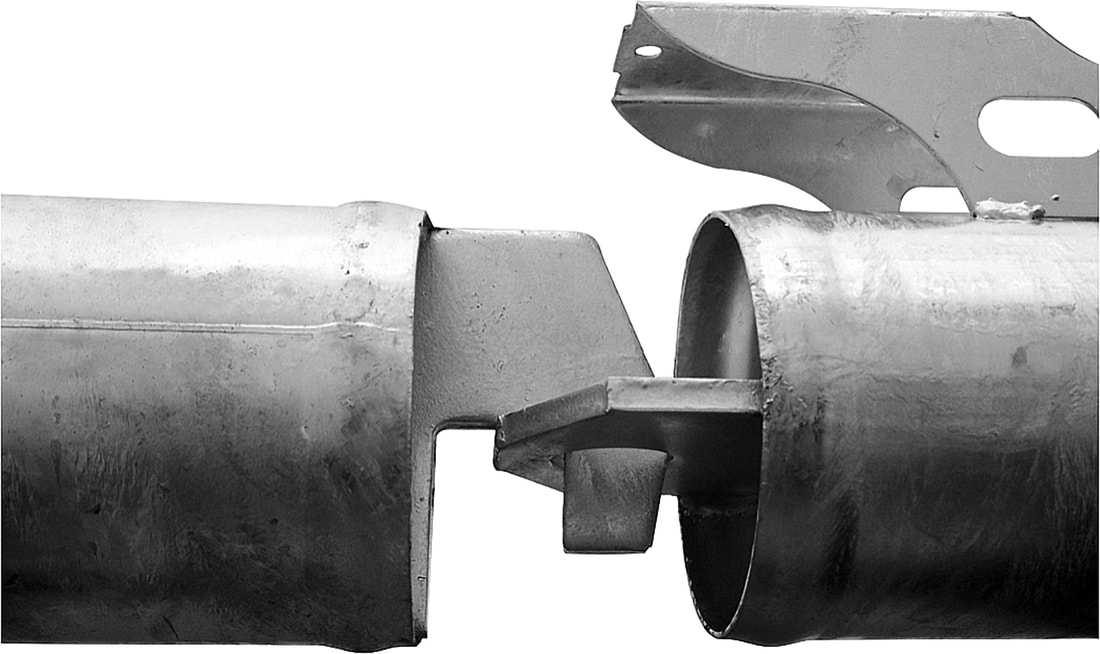

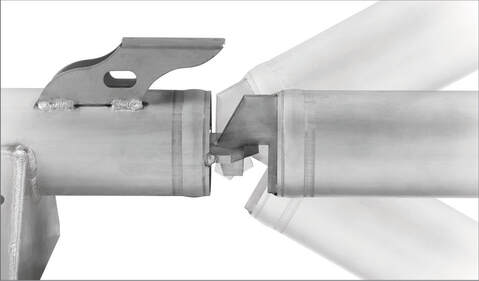

The flex joint hook and receiver is located where the water pipe meets the tower. Our unique joint provides unparalleled rotational movement and flexibility, allowing the system to adapt to your field’s changing and challenging terrain.

The joint is located inside the pipe and covered by an external, flexible boot, which is backed by a 10 year warranty. Why did we place the joint at the center of the pipe when our competitors use an external ball-hitch coupler? It’s really just a simple physics problem, as the most efficient place to rotate within a cylinder is directly in the center. The central joint allows the pipe to remain aligned with flex or rotation. Since the pipe remains aligned, the boot is not excessively stretched, which enhances the joint’s overall longevity.

You might wonder if the joint’s placement affects water flow. The answer is yes, a little. According to a Clemson University study, the effect is minimal. The competition has additional water flow disruption due to invasive pipe features like T-gaskets, flow-drilled couplers and misshapen span water-hose connections.

The proof is in the data. If you have inclined or bumpy terrain, you know how challenging it can be to attain even water application throughout the area. Clemson University tested the Reinke internal flex joint against a competitor’s external ball-hitch coupler. Researchers tested both joints

at alignment (flat) and at a 15-degree slope with flow rates ranging from 500 to 1,300 gallons per minute (GPM).

The flex joint hook and receiver is located where the water pipe meets the tower. Our unique joint provides unparalleled rotational movement and flexibility, allowing the system to adapt to your field’s changing and challenging terrain.

The joint is located inside the pipe and covered by an external, flexible boot, which is backed by a 10 year warranty. Why did we place the joint at the center of the pipe when our competitors use an external ball-hitch coupler? It’s really just a simple physics problem, as the most efficient place to rotate within a cylinder is directly in the center. The central joint allows the pipe to remain aligned with flex or rotation. Since the pipe remains aligned, the boot is not excessively stretched, which enhances the joint’s overall longevity.

You might wonder if the joint’s placement affects water flow. The answer is yes, a little. According to a Clemson University study, the effect is minimal. The competition has additional water flow disruption due to invasive pipe features like T-gaskets, flow-drilled couplers and misshapen span water-hose connections.

The proof is in the data. If you have inclined or bumpy terrain, you know how challenging it can be to attain even water application throughout the area. Clemson University tested the Reinke internal flex joint against a competitor’s external ball-hitch coupler. Researchers tested both joints

at alignment (flat) and at a 15-degree slope with flow rates ranging from 500 to 1,300 gallons per minute (GPM).

With a 15% slope and a flow rate of 1,300 GPM, the external ball-hitch coupler experienced a pressure drop per joint of 1.75 PSI, while the Reinke internal flex joint was less than 0.5. The incline pressure drop also was more significant for the external ball-hitch coupler at lower flow rates.

Overall, the flex joint hook and receiver allows Reinke systems to irrigate where other systems can’t. Ask your Reinke Certified Dealer about the

X-treme package for irrigation on steeper slopes.

Overall, the flex joint hook and receiver allows Reinke systems to irrigate where other systems can’t. Ask your Reinke Certified Dealer about the

X-treme package for irrigation on steeper slopes.

PRODUCTS |

FIND A DEALER |

RESOURCES |

ABOUT |

EMPLOYMENT |

© 2024 REINKE MANUFACTURING CO., INC.

ALL RIGHTS RESERVED

ALL RIGHTS RESERVED